Commonly used Inert Alumina Ceramic Ball chemical packing in actual production can be divided into three categories according to the raw materials they are produced: ceramic packing, plastic packing, and metal packing. According to the external shape, it can be divided into four categories: granular fillers, honeycomb or corrugated plate fillers, spherical lightweight ceramsite, and irregular porous fillers. Today we will briefly describe the most commonly used ceramic fillers as chemical fillers:

Ceramic tower packing are cheaper and have good surface wettability. In actual industrial applications, it has good acid resistance, alkali resistance, corrosion resistance, and high temperature resistance, is not easy to penetrate, does not react chemically with materials, and has low water absorption. It can withstand the corrosion of various organic acids and bases except fluorofluoric acid and fluorosilicic acid, and can withstand the corrosion of almost all concentrations of inorganic acids and salts as well as organic media. However, because ceramics contain a large amount of silica and alkali easily produces silicates, ceramic fillers have poor corrosion resistance to phosphoric acid.

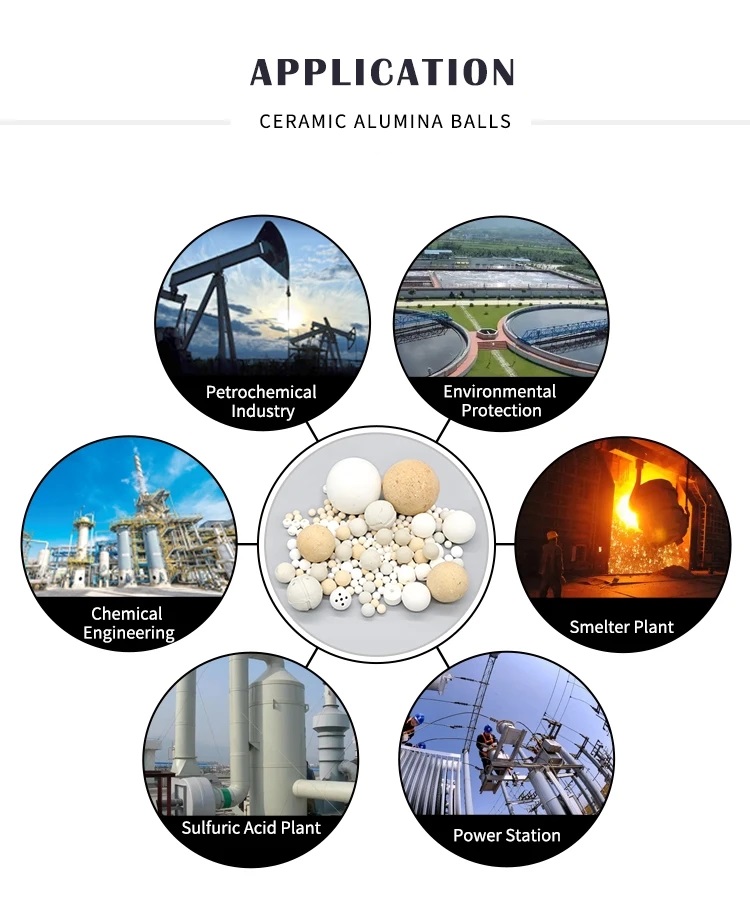

In practical applications, industrial ceramic packing are usually used in washing towers, cooling towers, recovery and regeneration towers, etc. in industries such as chemical industry, metallurgy, acid production, oxygen production, steel, electric power, papermaking, petroleum smelting, pharmaceuticals, gas, fine chemicals, and water treatment. It is used as lining material, filter material or tower packing in desulfurization tower, drying tower, absorption tower, filter tank and reactor. It is widely used in gas absorption, gas scrubbing, liquid extraction and other processes.

NEWSLETTER SIGNUP

By subscribing to our mailing list you will always be update with the latest news from us.

We never spam!

Copyright © Mingguang Feizhou new materials Co., Ltd. All Rights Reserved. | Sitemap | Technical Support: