Item | Molecular sieve 3A | |||

Shape | Pellet/Cylindrical | Sphere | ||

Typical Chemical Formula | Na2O . Al2O3 . 2 SiO2 . 4.5H2O SiO2 : Al2O3 ≈2 | |||

Diameter (mm) | 1.5-1.7 | 3.0-3.3 | 1.7-2.5 | 3.0-5.0 |

Size ratio up to grade (%) | ≥98 | ≥98 | ≥96 | ≥96 |

Bulk density (g/ml) | ≥0.65 | ≥0.65 | ≥0.70 | ≥0.70 |

Wear ratio (%) | ≤0.30 | ≤0.30 | ≤0.10 | ≤0.10 |

Crushing strength (N) | ≥30/cm | ≥70/cm | ≥30/piece | ≥80/piece |

Static water adsorption (%) | ≥21 | ≥21 | ≥21 | ≥21 |

Ethylene adsorption (‰) | ≤0.30 | ≤0.30 | ≤0.30 | ≤0.30 |

Water content, as shipped (%) | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 |

Application | - The strong ionic forces of the divalent calcium ion make it an excellent

| |||

Package | 50kg/steel drum | |||

PRODUCTS DESCRIPTION

Product description:

Molecular Sieves 3A Adsorbent is made from zeolite powder 3A (>70%) and binder. Zeolite powder 3A is a potassium based type A zeolite, which is generated by replacing part of sodium cation in 4 angstrom sieve. Molecular sieve 3A is usually used for dehydration. Since it only adsorb molecule with diameter less than 3 anstroms. Molecular sieve 3A is a perfect adsorbent if you only want to remove water from gas mixture in most condition. Molecular Sieve 3A have the shape of beads and pallets.

Dehydration unit pre-dryied 3-5mm spherical molecular sieve 3A

3A Molecular Sieve, is an alkali metal alumina silicate. It is the potassium form of the type A crystal structure. It has an effective pore opening of about 3 angstroms(0.3nm). This is large enough to allow in moisture, but excludes molecules such as unsaturated hydrocarbons which can potentially form polymers.

3A Molecular Sieve, has the advantages of faster adsorption speed, more regeneration times, higher crushing strength, stronger anti-pollution ability, greater utilization efficiency and longer service life.

Chemical Molecular Formula: 0.4K2O·0.6Na2O·Al2O3·2SiO2··4.5H2O. (SiO2 : Al2O3 ≈2).

Model | 3A Molecular Sieve | |||

Nominal pore diameter | 3 angstroms | |||

Shape | Sphere | Pellet | ||

Diameter | 1.7-2.5(mm) | 3.0-5.0(mm) | 1.6(mm) | 3.2(mm) |

Bulk density (g/ml) | ≥0.7 | ≥0.7 | ≥0.68 | ≥0.68 |

Crushing strength (N/PC) | ≥55.0 | ≥85.0 | ≥30.0 | ≥50.0 |

Size ratio up to grade (%) | ≥98.0 | ≥98.0 | ≥96.0 | ≥96.0 |

Static H2O adsorption (%) | ≥21.0 | ≥21.0 | ≥21.0 | ≥21.0 |

H2O content (%) | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 |

Wear ratio (%) | ≤0.25 | ≤0.25 | ≤0.25 | ≤0.25 |

More Details:

Synonym: Zeolite 3A, Molsive 3A, Zeolith 3A

Typical Chemical Formula: 0,45 K2O . 0,55 Na2O . Al2O3 . 2 SiO2 . n H2O

CAS NO.: 1318-02-1

Silica-alumina ratio: SiO2/ Al2O3≈2

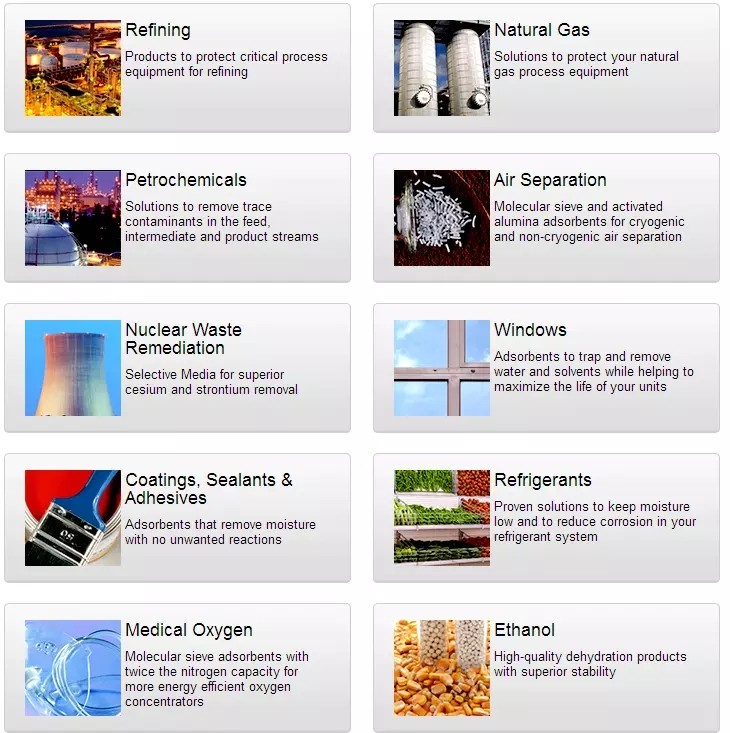

Molecular Sieve Beads For Drying Ethanol Application:

1. Zeolite molecular sieve 3A is used for drying of unsaturated hydrocarbons (e.g. ethylene, propylene, butadiene)

2. Zeolite molecular sieve 3A is used in deep desiccation of cracked petroleum gases, such as ethylene, propylene, butadiene, acetylene and natural gas, and of polar liquid, such as ethanol, LPG and solvent

3. Zeolite molecular sieve 3A is used in drying of natural gas, if COS minimization is essential, or a minimum co-adsorption of hydrocarbons is required

4. Zeolite molecular sieve 3A is used in drying of highly polar compounds, such as methanol and ethanol

5. Zeolite molecular sieve 3A is used in drying of refrigerants (e.g. XH-5, XH-7 etc)

6. Zeolite molecular sieve 3A is used in dehydration of benzene, toluene, xylene and other solvents

7. Zeolite molecular sieve 3A is used in static, (non-regenerative) dehydration of insulating glass units

Desiccant Storage:

Keep 3A molecular sieve in an air tight container until ready for use to avoid unintended moisture adsorption.

Regeneration&Activation:

Molecular sieve 3A can be regenerated or activated either thermal regeneration method(Thermal Swing Adsorption, TSA); To remove moisture from a 3A molecular sieve, a temperature of 200-230°C (390-570°F)is required. Molecular sieve 3A can also be regnerated or activated by lowering the pressure in the case of pressure swing processes (PSA). A properly regenerated or activated molecular sieve can give moisture dew points below -100°C. The outlet concentrations on a pressure swing process will depend on the gas present, and on the conditions of the process.

Packing:

150 kg/drum, 25kg/carton, supersack

"Note:This is normal specification, in case of a particular application, please contact us by email at info@fznewmaterials.com for technical information."

NEWSLETTER SIGNUP

By subscribing to our mailing list you will always be update with the latest news from us.

We never spam!

Copyright © Mingguang Feizhou new materials Co., Ltd. All Rights Reserved. | Sitemap | Technical Support: