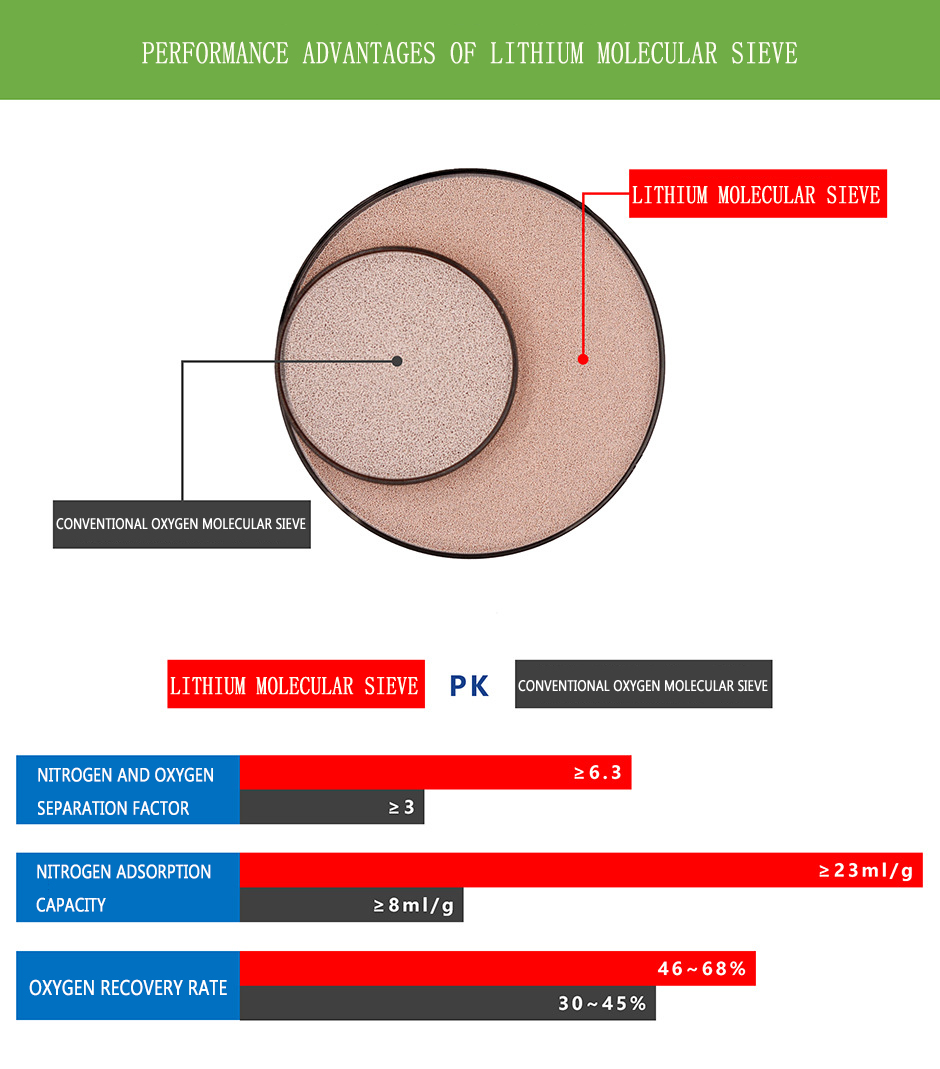

Lithium molecular sieve is a synthetic zeolite of lithium-type crystal structure, large Nitrogen adsorption capacity, highefficiency of oxygen/nitrogen separation. Below chart indicates lithium based molecular sieve((The temperature is 25℃)) It shows high N2/O2 separation under a very low pressure, which lowers the consumption of producing oxygen.The advantage of on the equilibrium adsorption capacity, It applies to various VPSA device for producing oxygen.

PRODUCTS DESCRIPTION

Lithium molecular sieve is a synthetic zeolite of lithium-type crystal structure, large Nitrogen adsorption capacity, high efficiency of oxygen/nitrogen separation. Below chart indicates lithium based molecular sieve((The temperature is 25℃))

item | value | |

Classification | Chemical Auxiliary Agent | |

CAS No. | 1318-02-1 | |

Model Number | LiLSX | |

Name | Lithium molecular sieve | |

color | light gray | |

Nominal pore diameter | 10 angstroms | |

Shape | Sphere Air Dryer Desiccant | |

Diameter(mm) | 0.4-0.8mm | 1.4-2.5mm |

Bulk density | 0.6g/ml | 0.63g/ml |

Loss on Ignition(wt%.575.C,1hr) | ≤1.0 | ≤1.0 |

Crushing Strength(N) | ≥5/piece | ≥12/piece |

Static N2 Capacity(wt%RH60%,25C) | ≥22 | ≥22 |

Attrition(wt%) | ≤0.2 | ≤0.2 |

Particle Ration(%) | ≥95 | ≥97 |

Water content(%) | ≤0.2 | ≤0.2 |

N2/O2Selectivity(a) | ≥6.2 | ≥6.2 |

Our Services

We hope we can bring you high quality service.

Our whole staff would keep hard and innovative in work to provide qualified product and good service.

Hand & Storage Recommendation

Molecular Sieve should be handled to avoid generation of dusty conditions at the workplace. Storage in a dry warehouse is recommended. Open packages should be resealed to prevent contamination and adsorption of water or other gases and vapors. The material in bag-in-box should be used within 12 months,while bag-in-steel drum should be used within 24 months.

Packaging & Shipping

1. Packaging Details:25KG net woven bag with inner plastic bag. 50KG net in Cardboard Drum. and other packing.You can also choose according to your requirements

2.Delivery Detail:We always provide sea transportation and air transportation.We can also provide according to your requirements.

3.Delivery time:Because of the nature of our products,we always delivery in 21 days.

Regeneration

To achieve good operating performance and long life as much as possible, after a certain period of time use must be regenerated .After correct molecular sieve regeneration , make it get the low attenuation of mechanical properties and adsorption

There are two basic approaches:

Temperature variation .

Generally used in the preheating gas heating, purge molecular sieve to about 200℃, and stripping down the adsorbate .

Variable pressure .

Usually used in the gas phase adsorption process.Maintain a constant temperature adsorbent and by reducing pressure and backing purge inert gas , to remove the adsorbate.

"Note:This is normal specification, in case of a particular application, application, please contact us by email at info@fznewmaterials.com for technical information."

NEWSLETTER SIGNUP

By subscribing to our mailing list you will always be update with the latest news from us.

We never spam!

Copyright © Mingguang Feizhou new materials Co., Ltd. All Rights Reserved. | Sitemap | Technical Support: