PRODUCTS DESCRIPTION

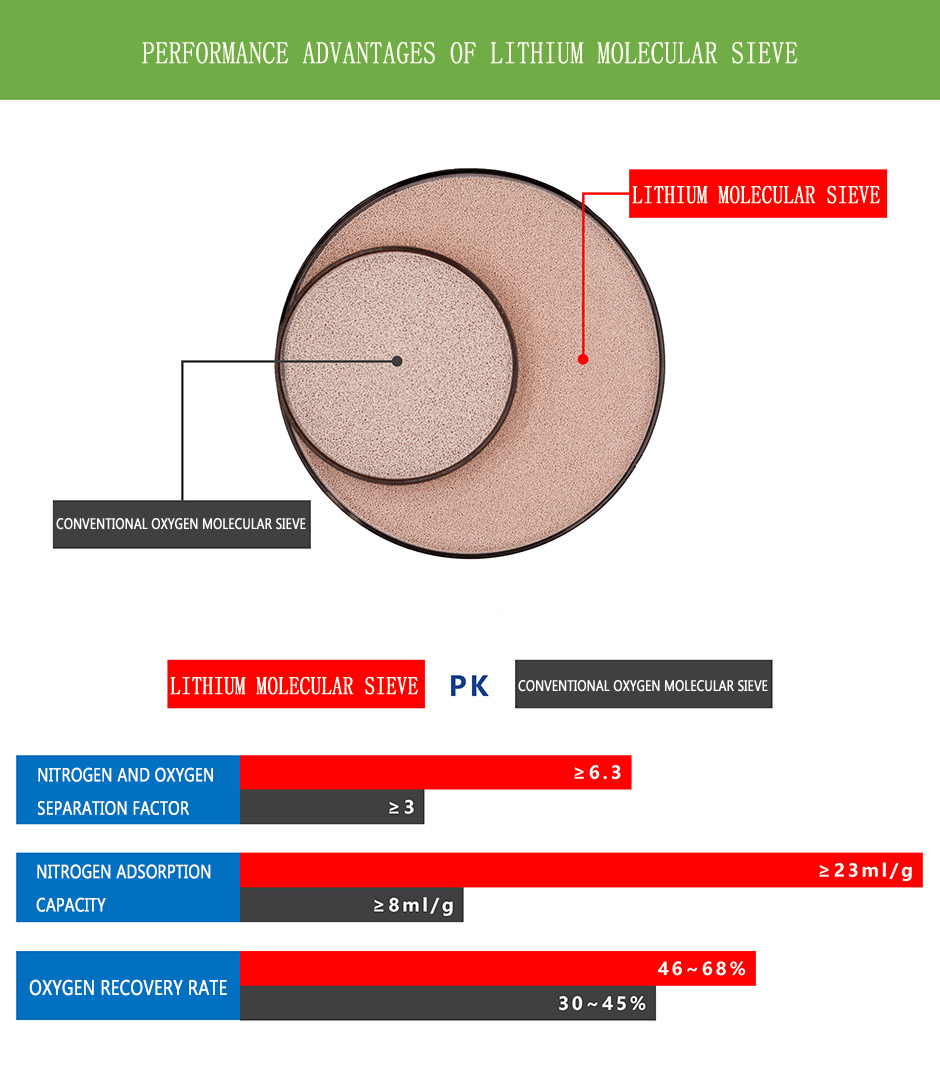

Lithium molecular sieve is a synthetic zeolite of lithium-type crystal structure, large Nitrogen adsorption capacity, highefficiency of oxygen/nitrogen separation. Below chart indicates lithium based molecular sieve((The temperature is 25℃)) It shows high N2/O2 separation under a very low pressure, which lowers the consumption of producing oxygen.The advantage of on the equilibrium adsorption capacity, It applies to various VPSA device for producing oxygen.

item | value | |

Classification | Chemical Auxiliary Agent | |

CAS No. | 1318-02-1 | |

Model Number | FEIZHOU-LiLSX | |

Name | Lithium molecular sieve | |

color | light gray | |

Nominal pore diameter | 10 angstroms | |

Shape | Sphere Air Dryer Desiccant | |

Diameter(mm) | 0.4-0.8mm | 1.6-2.5mm |

Bulk density | 0.6g/ml | 0.63g/ml |

Loss on Ignition(wt%.575.C,1hr) | ≤1.0 | ≤1.0 |

Crushing Strength(N) | ≥5/piece | ≥12/piece |

Static N2 Capacity(wt%RH60%,25C) | ≥22 | ≥22 |

Attrition(wt%) | ≤0.2 | ≤0.2 |

Particle Ration(%) | ≥95 | ≥97 |

Water content(%) | ≤0.2 | ≤0.2 |

N2/O2Selectivity(a) | ≥6.2 | ≥6.2 |

Our Services

We hope we can bring you high quality service.

Our whole staff would keep hard and innovative in work to provide qualified product and good service.

Hand & Storage Recommendation

Molecular Sieve should be handled to avoid generation of dusty conditions at the workplace. Storage in a dry warehouse is recommended. Open packages should be resealed to prevent contamination and adsorption of water or other gases and vapors. The material in bag-in-box should be used within 12 months,while bag-in-steel drum should be used within 24 months.

Package of lithium & Sodium molecular sieve:

25kg & 125kg / steel drum. palletized with plastic film for lithium molecular sieve

1. Packaging Details:25KG net woven bag with inner plastic bag. 50KG net in Cardboard Drum. and other packing.You can also choose according to your requirements

2.Delivery Detail:We always provide sea transportation and air transportation.We can also provide according to your requirements.

3.Delivery time:Because of the nature of our products,we always delivery in 21 days.

Regeneration

To achieve good operating performance and long life as much as possible, after a certain period of time use must be regenerated .After correct molecular sieve regeneration , make it get the low attenuation of mechanical properties and adsorption

There are two basic approaches:

Temperature variation .

Generally used in the preheating gas heating, purge molecular sieve to about 200℃, and stripping down the adsorbate .

Variable pressure .

Usually used in the gas phase adsorption process.Maintain a constant temperature adsorbent and by reducing pressure and backing purge inert gas , to remove the adsorbate.

"Note:This is normal specification, in case of a particular application, application, please contact us by email at info@fznewmaterials.com for technical information."

NEWSLETTER SIGNUP

By subscribing to our mailing list you will always be update with the latest news from us.

We never spam!

Copyright © Mingguang Feizhou new materials Co., Ltd. All Rights Reserved. | Sitemap | Technical Support: