13X Molecular sieves have strong hygroscopicity and should be used for purification of gases. When preserved, direct exposure to air should be avoided. Molecular sieves with long storage time and moisture absorption should be regenerated before use. Molecular sieves avoid oil and liquid water. Avoid contact with oil and liquid water when using. In industrial production, the drying gases are air, hydrogen, oxygen, nitrogen, argon and so on. Two adsorption dryers are connected in parallel, one working, and the other can be regenerated. Alternate work and regeneration to ensure continuous operation of equipment. The dryer works at room temperature and regenerates by flushing air at 350 C.

PRODUCTS DESCRIPTION

13X Molecular Sieve

Item | Unit | Technical data | |||

Shape | Pellet | Sphere | |||

Diameter | mm | 1.5-1.7 | 3.0-.3.3 | 1.7-2.5 | 3.0-5.0 |

Size ratio up to grade | % | ≥98 | ≥98 | ≥96 | ≥96 |

Bulk density | g/ml | ≥0.68 | ≥0.68 | ≥0.68 | ≥0.68 |

Wear ratio | % | ≤0.10 | ≤0.20 | ≤0.10 | ≤0.10 |

Crushing strength | N | ≥30/cm | ≥45/cm | ≥25/piece | ≥65/piece |

Static water adsorption | % | ≥23.5 | ≥23.5 | ≥23.5 | ≥23.5 |

Static CO2 adsorption | % | ≥18 | ≥18 | ≥18 | |

Water content,as shipped | % | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 |

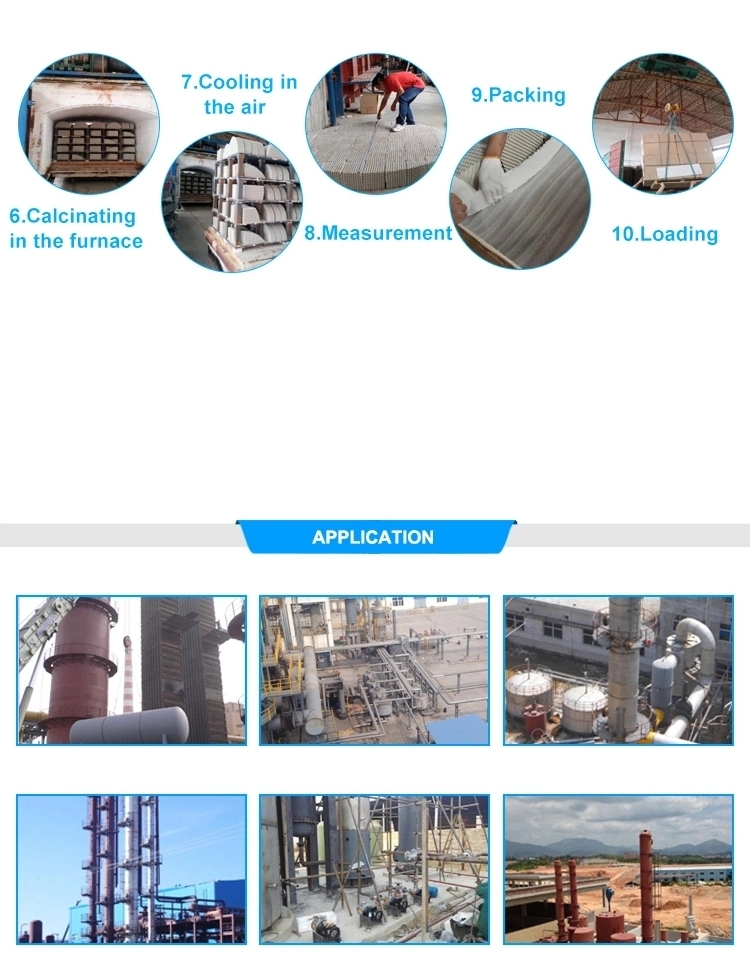

Application

1) Removal of CO2 and moisture from air (air pre-purification) and other gases.

2) Separation of enriched oxygen from air.

3) Removal of mercaptans and hydrogen sulphide from natural gas.

4) Removal of mercaptans and hydrpogen sulphide from hydrocarbon liquid streams (LPG, butane, propane etc.)

5) Catalyst protection, removal of oxygenates from hydrocarbons (olefin streams).

6) Removal of n-chained compositions from aromatics.

7) Production of bulk oxygen in PSA units.

8) Production of medical oxygen in small scale oxygen concentrators

Storage:

Keep 13X Molecular Sieve in an air tight container until ready for use to avoid unintended moisture adsorption.

Regeneration&Activation:

Molecular sieve 13X can be regenerated either thermal regeneration method(Thermal Swing Adsorption, TSA); To remove moisture from a 13X molecular sieve, a temperature of 200-230℃ (390-570°F) is required. Molecular sieve 13X can also be regnerated by lowering the pressure in the case of pressure swing processes (PSA). A properly regenerated molecular sieve can give moisture dew points below -100℃. The outlet concentrations on a pressure swing process will depend on the gas present, and on the conditions of the process.

Packing

140 kg/drum, 25kg/carton, supersack

"Note:This is normal specification, in case of a particular application, please contact us by email at info@fznewmaterials.com for technical information."

Zeolite Molecular Sieve Beads 13X Zeolite Molecular Sieve Drying Use In Air Compressor System Removal of H2O Mercaptans Sulphur Compounds for Moisture Removal

Zeolite Molecular Sieve Beads 13X Zeolite Molecular Sieve Drying Use In Air Compressor System Removal of H2O Mercaptans Sulphur Compounds for Moisture Removal NEWSLETTER SIGNUP

By subscribing to our mailing list you will always be update with the latest news from us.

We never spam!

Copyright © Mingguang Feizhou new materials Co., Ltd. All Rights Reserved. | Sitemap | Technical Support: