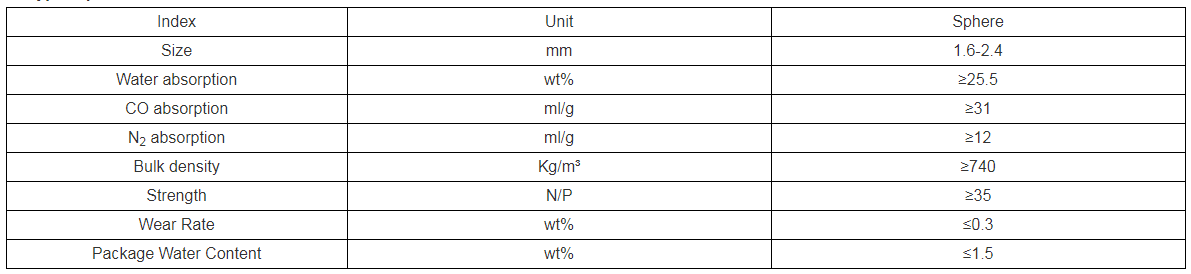

Model | 5A Molecular Sieve | |||

Nominal pore diameter | 5 angstroms | |||

Shape | Sphere | Pellet | ||

Diameter | 1.7-2.5 (mm) | 3.0-5.0 (mm) | 1.6 (mm) | 3.2 (mm) |

8*12 (mesh) | 4*8 (mesh) | 1/16 (inch) | 1/8 (inch) | |

Bulk density (g/ml) | ≥0.66 | ≥0.66 | ≥0.64 | ≥0.64 |

Crushing strength (N/PC) | ≥30.0 | ≥70.0 | ≥30.0 | ≥50.0 |

Size ratio up to grade (%) | ≥96.0 | ≥96.0 | ≥96.0 | ≥94.0 |

Static H2O adsorption (%) | ≥21.0 | ≥21.0 | ≥20.5 | ≥20.5 |

Static Hexane adsorption (%) | ≥12.0 | ≥12.0 | ≥12.0 | ≥12.0 |

H2O content (%) | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 |

Wear ratio (%) | ≤0.20 | ≤0.20 | ≤0.40 | ≤0.40 |

PRODUCTS DESCRIPTION

Product description:

Standard molecular sieve 5A is made from zeolite powder 5A (>70%) and binder. Binder is clay, which has little adsorption capacity. Binderless 5A transforms clay binder to zeolite 5A. That means zeolite 5A composition in binderless molecular sieve 5A is 100%, that greatly increased its adsorption capacity. Hydrogen purification molecular sieve 5A is normally used in PSA hydrogen purification. Hydrogen purification 5A has the advantages of a large adsorption capacity, fast adsorption&desorption rate and high mechanical strength. Hydrogen purification molecular sieve 5A greatly increased the CO, N2 and CH4 adsorption capacity than standard molecular sieve 5A, which makes it an excellent adsorbents for PSA hydrogen purification process. Hydrogen purification molecular Sieve 5A have the shape of beads with diameter 1.6-2.5 mm (8x12 mesh).

More Details:

1. Synonym: PSA 5A

2. Typical Chemical Formula: Ca4,5 [(Al02)12(SiO2)12].nH2O

3. CAS NO.: 1318-02-1

4. Silica-alumina ratio: SiO2/ Al2O3≈2

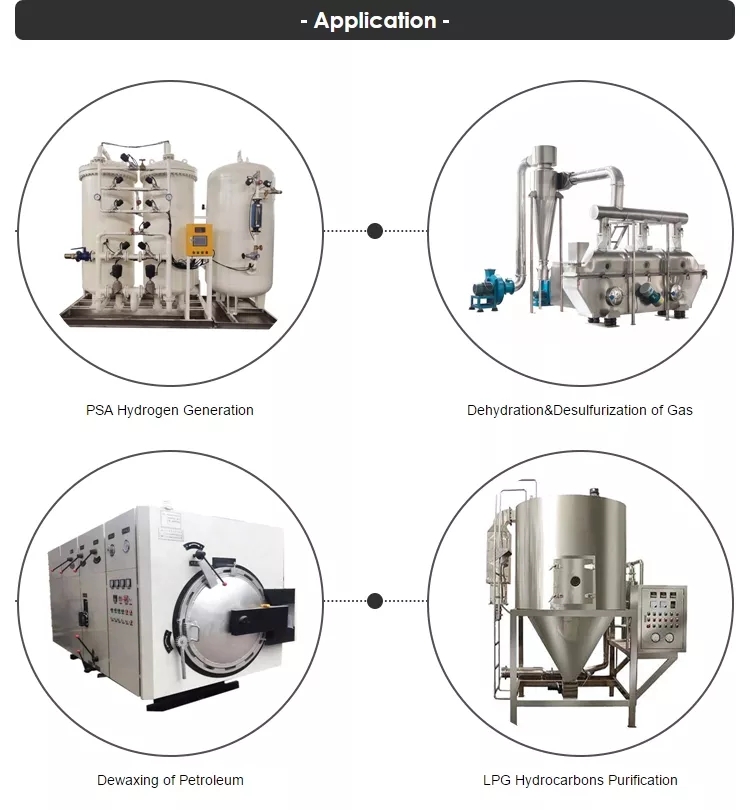

Application:

1. Hyrogen purification molecular sieve 5A is used for hydrogen Purification by PSA method

2. Hyrogen purification molecular sieve 5A can also be used in PSA oxygen concentrator

Stroage:

Keep hydrogen purification molecular sieve 5A in an air tight container until ready for use to avoid unintended moisture adsorption.

Regeneration & Activation:

Hyrogen purification molecular sieve 5A can be regenerated or activated either thermal regeneration method(Thermal Swing Adsorption, TSA); To remove moisture from a Hyrogen purification molecular sieve 5A, a temperature of 200-230℃ (390-570°F)is required. Hyrogen purification molecular sieve 5A can also be regnerated by lowering the pressure in the case of pressure swing processes (PSA). A properly regenerated molecular sieve can give moisture dew points below -100℃. The outlet concentrations on a pressure swing process will depend on the gas present, and on the conditions of the process.

Packing:

"Note:This is normal specification, in case of a particular application, please contact us by email at info@fznewmaterials.com for technical information."

NEWSLETTER SIGNUP

By subscribing to our mailing list you will always be update with the latest news from us.

We never spam!

Copyright © Mingguang Feizhou new materials Co., Ltd. All Rights Reserved. | Sitemap | Technical Support: